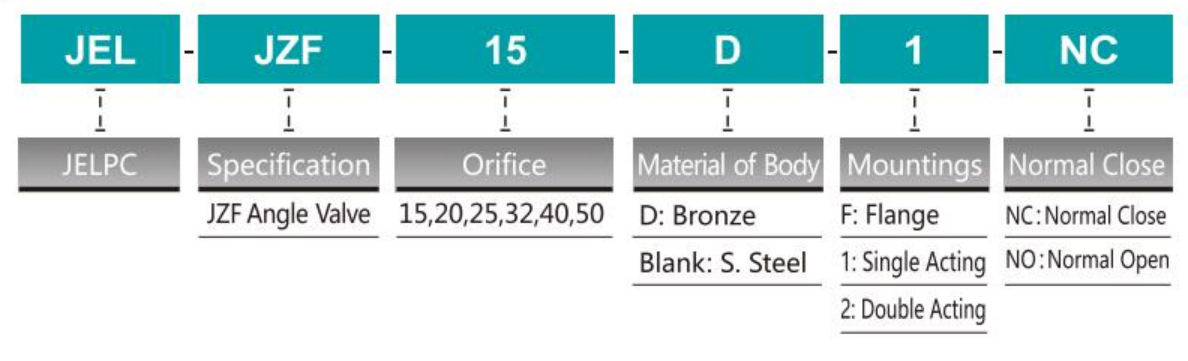

Ordering Code

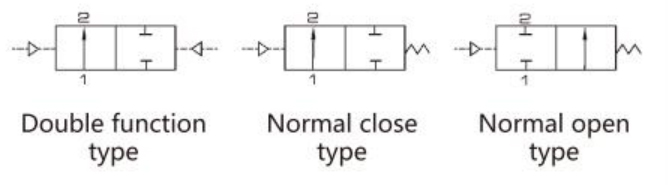

Symbol

Specification

| Orifice size (mm) |

Port Thread (PT) |

Kv (m³/h) |

Max.Working Pressure (MPa) |

Required Min. Control Pressure (MPa) |

PA | Medium Temperature |

Direction |

| 15 | PT1/2" | 4.2 | 0~1.6 | 0.39 | 50 | -10~+180℃ | Direction A or B |

| 20 | PT3/4" | 8 | 0~1.1 | 0.39 | 50 | ||

| 25 | PT1" | 19 | 0~1.1 | 0.42 | 63 | ||

| 32 | PT11/4" | 27.5 | 0~1.5 | 0.5 | 63 | ||

| 40 | PT1/2" | 42 | 0~1.25 | 0.44 | 63 | ||

| 50 | PT2" | 55 | 0~1.0 | 0.4 | 80 | ||

| 65 | PT2'/2" | 65 | 0~1.0 | 0.4 | 100 |

Fix and Maintain

1. Clean the pipes carefully from any residue, dribble or welding residue, to avoid any damage to the seal.

2. To be installed as required, preferably with actuator in upright position.

3. Connect the pipes according to the reference points (flow direction) found on the valve body. Only disasemble actuator if required by customer.

4. Before taking the valve apart, depressurize the medium supply and piloted air supply from piping system.

Internal Structure

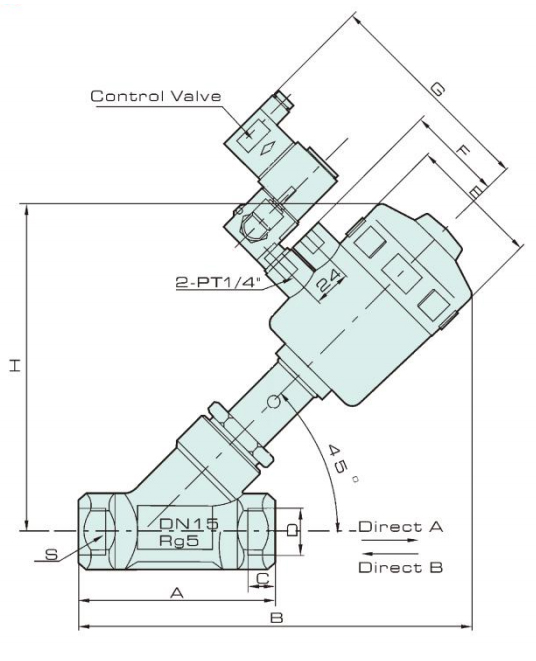

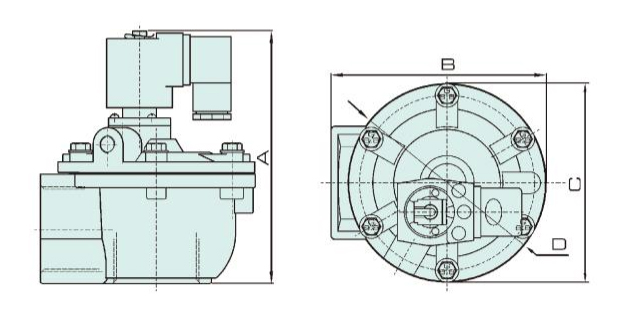

Overall Dimension

Dimension

|

Orifice(mm) |

Port Thread D |

Execution Device |

|

B |

|

∅E |

F |

G |

H |

L |

S |

||||||

|

PA |

aluminium |

A |

PA |

aluminium |

C |

PA |

aluminium |

PA |

aluminium |

PA |

aluminium |

PA |

aluminium |

||||

|

15 |

PT1/2" |

50 |

- |

85 |

173 |

- |

12 |

64 |

- |

44 |

- |

112 |

- |

137 |

- |

33 |

27 |

|

20 |

PT3/4" |

50 |

- |

95 |

178 |

- |

12 |

64 |

- |

44 |

- |

112 |

- |

145 |

- |

35 |

32 |

|

25 |

PT1" |

63 |

- |

105 |

212 |

- |

14 |

80 |

- |

52 |

- |

120 |

- |

173 |

- |

40 |

41 |

|

32 |

PT1/4" |

63 |

100 |

118 |

236 |

276 |

16 |

80 |

140 |

52 |

70 |

120 |

138 |

189 |

250 |

35 |

55 |

|

40 |

PT1/2" |

63 |

100 |

130 |

230 |

270 |

18 |

80 |

140 |

52 |

70 |

120 |

138 |

189 |

250 |

35 |

55 |

|

50 |

PT2" |

80 |

125 |

150 |

238 |

300 |

20 |

100 |

170 |

52 |

83 |

120 |

151 |

250 |

260 |

38 |

70 |

|

65 |

PT2/2" |

100 |

- |

155 |

300 |

- |

25 |

125 |

- |

62 |

- |

130 |

- |

265 |

- |

48 |

80 |

Note

*Features while select A type flow direction increase service life.

Prevent water impact when working medium is liquid.

Product with orifice size at 015, 020 or 225,itis necessary to keep working pressure under 0.3 Mpa, otherwise double-acting actuators should be adopted.

Product with orifice size at 032 or 040, double-acting actuators should be 0100.

Product with orifice size at 050, double-acting actuators should be 0125.

*Features while select B type flow direction

Sealing property can be improved under B type flow direction while medium is steam or liquid. if the V shape sealing contact with working medium is too long, and it will influence on service life. Apart from that, the anti-water impact does not exit when working medium is liquid.