Features:

1. Improving for adapting wide range applications, using precise polishing of piston rod, more sense of products quality and longer life of front seal.

2. Optima design and improve the production efficiency.

3. Combined with enterprise color planning and new structure design.

4. Change processing technology of cylinder cushion structure to ensure buffering function in stabilization.

5. Improved the range of buffering fine-tune, enable customers to more easily adjust the buffer throttling speed.

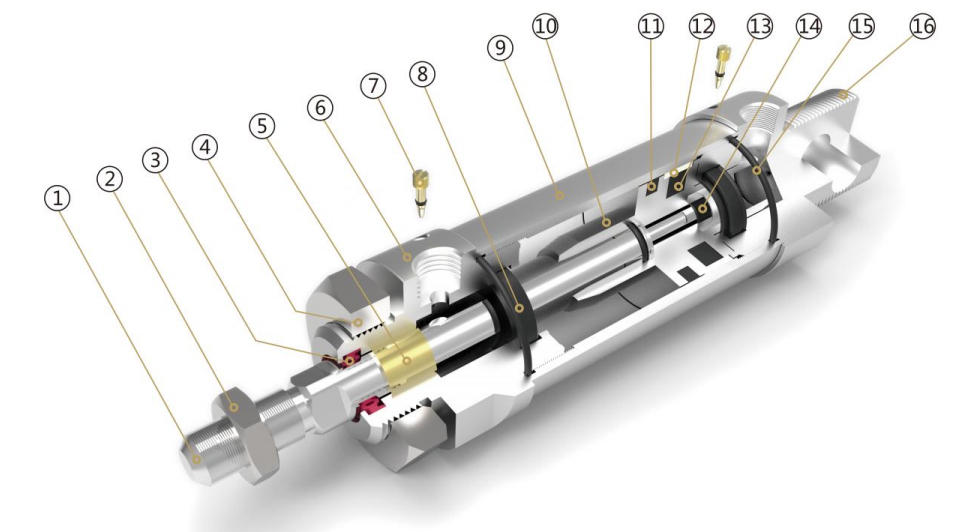

Internal Structure

Parts

| Number | Name | Number | Name |

| 1 | Piston rod | 9 | Barrel |

| 2 | Hexagon nut | 10 | Piston |

| 3 | Shaft seal | 11 | Piston seal |

| 4 | Hexagon nut | 12 | Anti-friction seal |

| 5 | DU bearing | 13 | Magnet |

| 6 | Front cover | 14 | Screw |

| 7 | Anti-collision gasket | 15 | O ring |

| 8 | Cushion | 16 | Back cover |

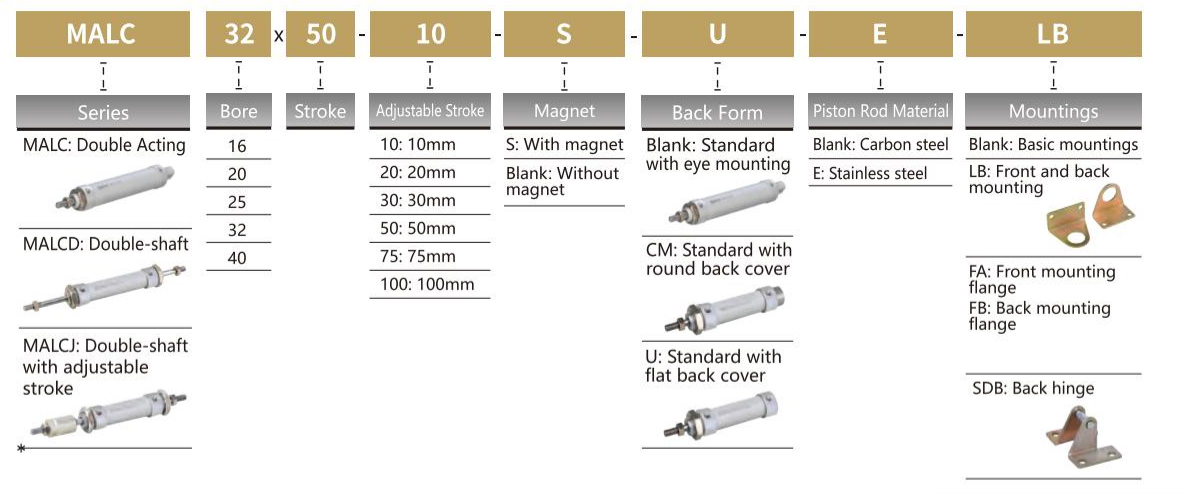

Ordering Code

*Sensor model JEL-01, Strap type "SKL-Bore" , please refer to P173 for the specific orderingcode.

Specification

| Bore(mm) | 16 | 20 | 25 | 32 | 40 |

| Operation | Double Acting | ||||

| Working Medium | Air | ||||

| Mountings | Basic LB FA FB SDB | ||||

| Operating Pressure Range | 0.1~1.0MPa | ||||

| Proof Pressure | 1.5 MPa | ||||

| Operating Temperature Range | -20~80℃ | ||||

| Operating Speed Range | 50~800mm/s | ||||

| Cushion | Adjustable Air Cushion | ||||

| Port Size | M5×0.8 | G1/8" | G1/4" | ||

Stroke

| Bore | Standard Stroke | Max. Stroke | |

| MALC | 16/20/25/32/40 | 15 20 25 30 40 50 60 75 80 100 125 150 160 175 200 250 275 300 | 500 |

| MALCD/MALCJ | 16/20/25/32/40 | 15 20 25 30 40 50 60 75 80 100 125 150 160 175 200 250 275 300 | 300 |

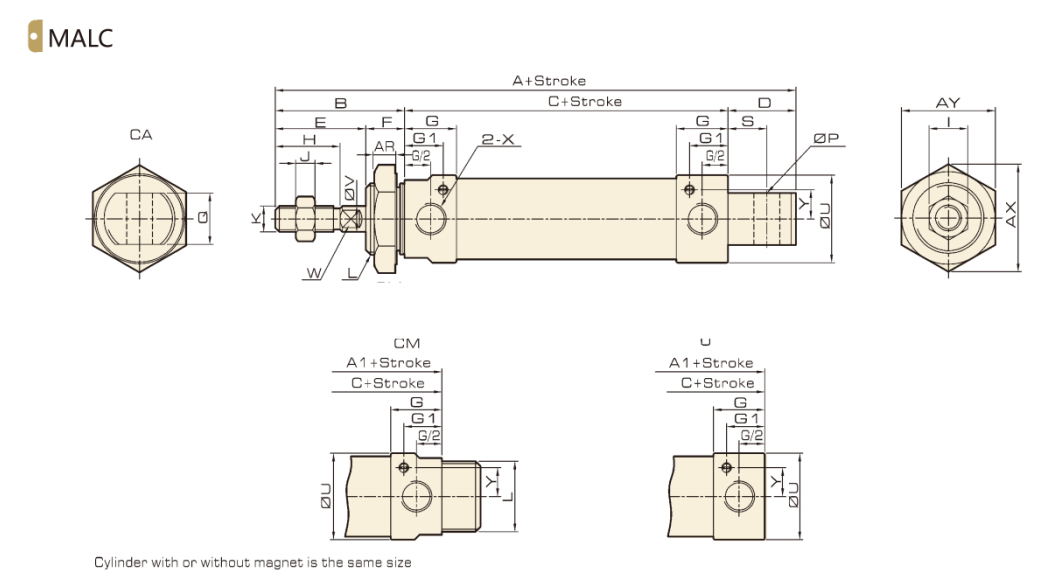

Overall Dimension

Dimension

| Bore/Stroke | A | A1 | B | C | D | D1 | E | F | G | G1 | H | I | J | K | |||||||||

| 16 | 105 | 90 | 38 | 52 | 15 | 12 | 24 | 14 | 11 | 6.5 | 16 | 10 | 5 | M6×1 | |||||||||

| 20 | 131 | 110 | 40 | 70 | 21 | 12 | 28 | 12 | 16 | 12 | 20 | 12 | 6 | M8×1.25 | |||||||||

| 25 | 135 | 114 | 44 | 70 | 21 | 14 | 30 | 14 | 16 | 11 | 22 | 17 | 6 | M10×1.25 | |||||||||

| 32 | 141 | 114 | 44 | 70 | 27 | 14 | 30 | 14 | 16 | 11.5 | 22 | 17 | 6 | M10×1.25 | |||||||||

| 40 | 165 | 138 | 46 | 92 | 27 | 14 | 32 | 14 | 22 | 15 | 24 | 19 | 7 | M12×1.25 | |||||||||

| Bore/Stroke | L | P | Q | S | U | V | W | X | AR | AX | AY | Y | |||||||||||

| 16 | M16×1.5 | 6 | 12 | 6 | 21 | 6 | 5 | M5×0.8 | 6 | 27.8 | 24 | 6 | |||||||||||

| 20 | M22×1.5 | 8 | 16 | 12 | 27 | 8 | 6 | G1/8 | 7 | 33.5 | 29 | 9 | |||||||||||

| 25 | M22×1.5 | 8 | 16 | 12 | 32 | 10 | 8 | G1/8 | 7 | 33.5 | 29 | 9 | |||||||||||

| 32 | M24×2 | 10 | 16 | 15 | 39.5 | 12 | 10 | G1/8 | 9 | 37 | 32 | 11.5 | |||||||||||

| 40 | M30×2 | 12 | 20 | 15 | 47 | 16 | 14 | G1/4 | 9 | 46 | 40 | 14 | |||||||||||

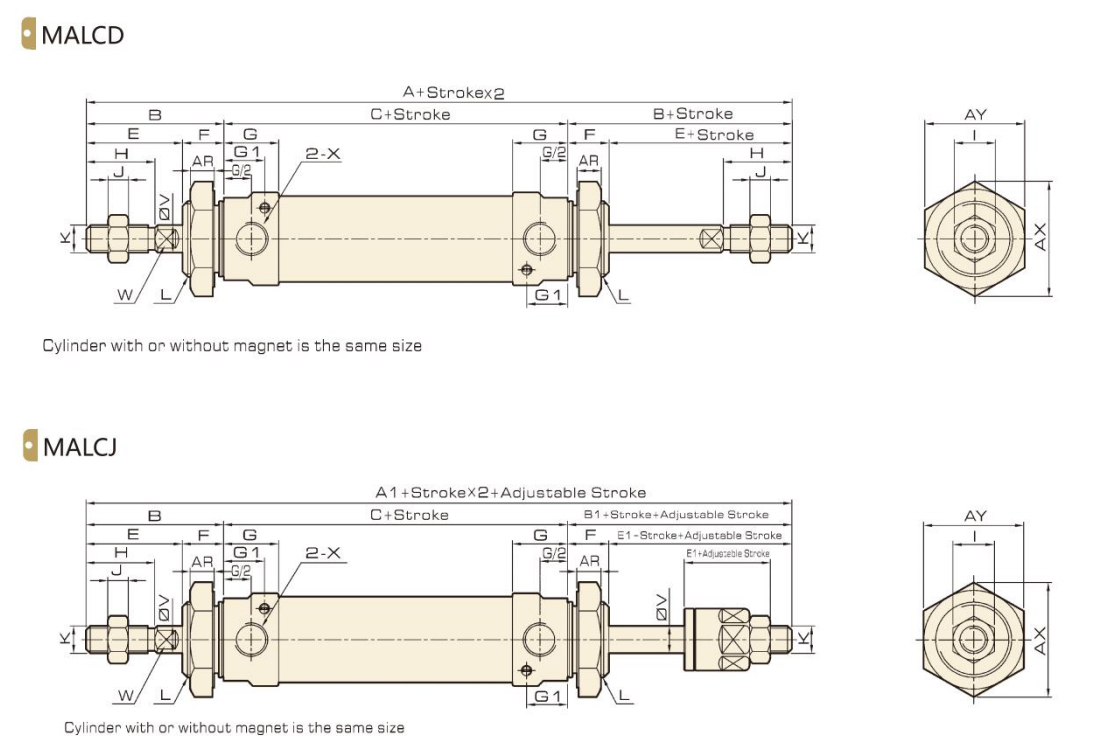

Overall Dimension

Dimension

| Bore Symbol | A | A1 | B | B1 | C | E | E1 | F | G | G1 | H | I | J | K | L | U | V | W | X | AR | AX | AY | Y |

| 16 | 128 | 125 | 38 | 35 | 52 | 24 | 21 | 14 | 11 | 6.5 | 16 | 10 | 5 | M6×1 | M16×1.5 | 21 | 6 | 5 | M5×0.8 | 6 | 27.8 | 24 | 6 |

| 20 | 150 | 147 | 40 | 37 | 70 | 28 | 25 | 12 | 16 | 12 | 20 | 12 | 6 | M8×1.25 | M22×1.5 | 27 | 8 | 6 | G1/8 | 7 | 33.5 | 29 | 9 |

| 25 | 158 | 155 | 44 | 41 | 70 | 30 | 27 | 14 | 16 | 11 | 22 | 17 | 6 | M10×1.25 | M22×1.5 | 32 | 10 | 8 | G1/8 | 7 | 33.5 | 29 | 9 |

| 32 | 158 | 155 | 44 | 41 | 70 | 30 | 27 | 14 | 16 | 11.5 | 22 | 17 | 6 | M10×1.25 | M24×2 | 39.5 | 12 | 10 | G1/8 | 9 | 37 | 32 | 11.5 |

| 40 | 184 | 180 | 46 | 42 | 92 | 32 | 28 | 14 | 22 | 15 | 24 | 19 | 7 | M12×1.25 | M30×2 | 47 | 16 | 4 | G1/4 | 9 | 46 | 40 | 14 |

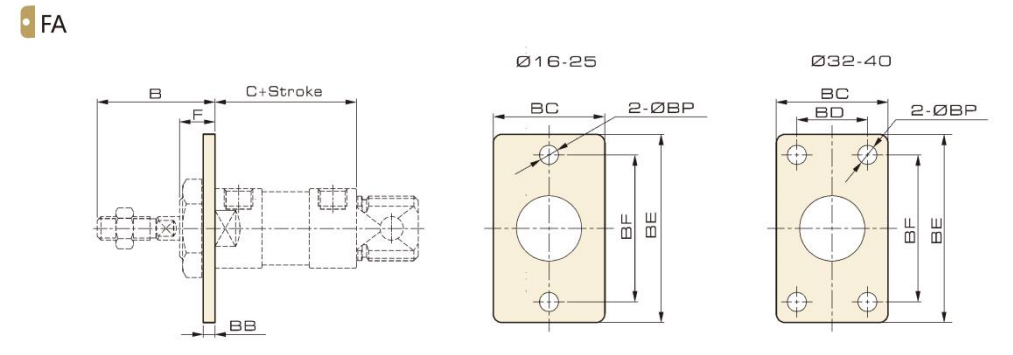

Overall Dimension

Dimension

| Symbol | B | C(MAL Series) | C (MSAL/MTAL Series) | BB | BC | BD | BE | BF | BP | F | ||

| Bore/Stroke | 0-50 | 50-100 | 100-150 | |||||||||

| 16 | 38 | 52 | 77 | 102 | - | 3 | 26 | - | 52 | 40 | 5.5 | 14 |

| 20 | 40 | 70 | 95 | 120 | 145 | 4 | 38 | - | 64 | 50 | 6.5 | 12 |

| 25 | 44 | 70 | 95 | 120 | 145 | 4 | 38 | - | 64 | 50 | 6.5 | 14 |

| 32 | 44 | 70 | 95 | 120 | 145 | 4 | 47 | 33 | 72 | 58 | 6.5 | 14 |

| 40 | 46 | 92 | 117 | 142 | 167 | 4 | 50 | 36 | 84 | 70 | 6.5 | 14 |

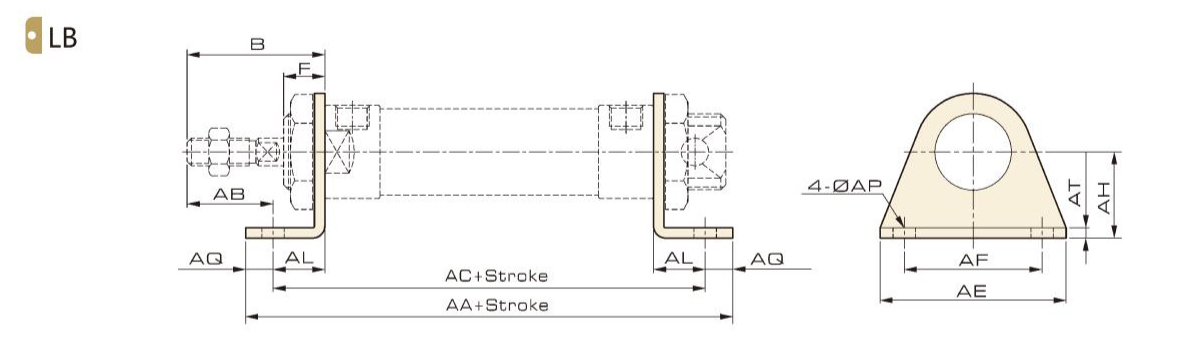

Overall Dimension

Dimension

|

Symbol |

B |

AA(MAL Series) |

AA(MSAL/MTAL Series) |

AB |

AC(MAL Series) |

AC(MSAL/MTAL Series) |

AE |

AF |

AH |

AL |

AP |

AQ |

AT |

F |

||||

|

Bore/Stroke |

0-50 |

50-100 |

100-150 |

0-50 |

50-100 |

100-150 |

||||||||||||

|

16 |

38 |

90 |

115 |

140 |

- |

25 |

78 |

103 |

128 |

- |

44 |

32 |

20 |

13 |

5.5 |

6 |

3 |

14 |

|

20 |

40 |

116 |

141 |

166 |

191 |

25 |

100 |

125 |

150 |

175 |

54 |

40 |

25 |

15 |

6.5 |

8 |

3 |

12 |

|

25 |

44 |

116 |

141 |

166 |

191 |

29 |

100 |

125 |

150 |

175 |

54 |

40 |

25 |

15 |

6.5 |

8 |

3 |

14 |

|

32 |

44 |

136 |

161 |

186 |

211 |

19 |

120 |

145 |

170 |

195 |

59 |

45 |

32 |

25 |

6.5 |

8 |

4 |

14 |

|

40 |

46 |

158 |

183 |

208 |

233 |

21 |

142 |

167 |

192 |

217 |

64 |

50 |

36 |

25 |

6.5 |

8 |

4 |

14 |

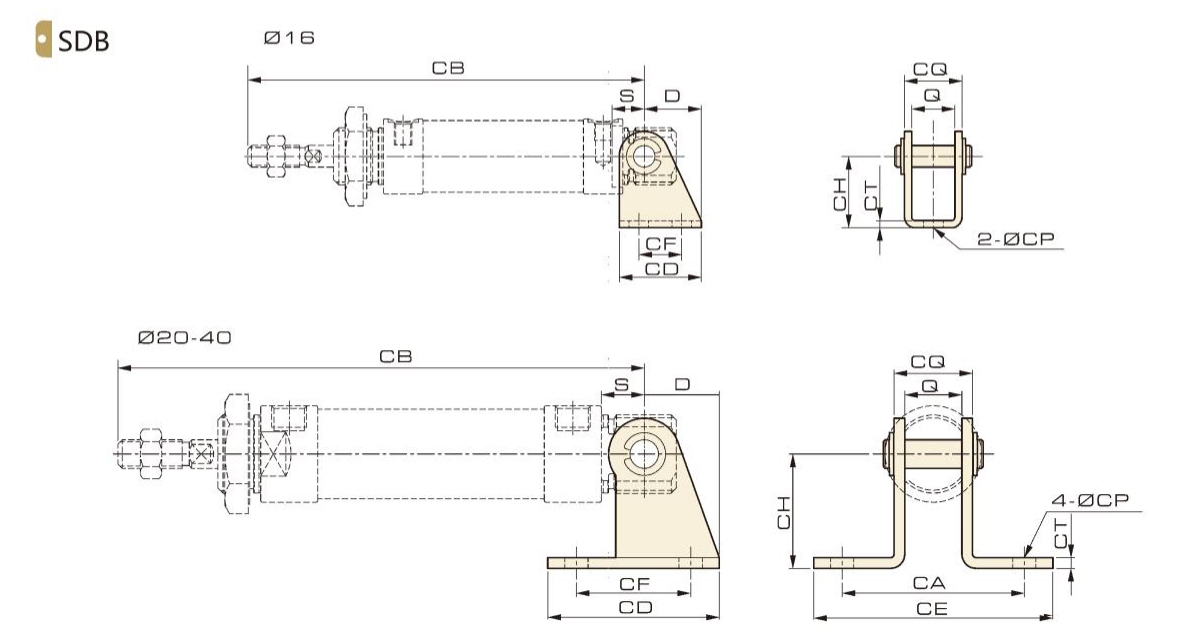

Overall Dimension

Dimension

| Symbol | D | S | Q | CA | CB(MAL Series) | CB(MSAL/MTAL Series) | CD | CE | CF | CH | CT | CP | CQ | ||

| Bore/Stroke | 0-50 | 50-100 | 100-150 | ||||||||||||

| 16 | 16 | 9 | 12 | - | 96 | 121 | 146 | - | 23 | - | 12 | 20 | 2 | 5.5 | 16 |

| 20 | 21 | 12 | 16 | 51 | 122 | 147 | 172 | 197 | 48 | 67 | 32 | 32 | 3 | 6.5 | 22 |

| 25 | 21 | 12 | 16 | 51 | 126 | 151 | 176 | 201 | 48 | 67 | 32 | 32 | 3 | 6.5 | 22 |

| 32 | 27 | 15 | 16 | 51 | 129 | 154 | 179 | 204 | 52 | 67 | 36 | 36 | 4 | 6.5 | 24 |

| 40 | 27 | 15 | 20 | 55 | 153 | 178 | 203 | 228 | 56 | 71 | 40 | 40 | 4 | 6.5 | 28 |

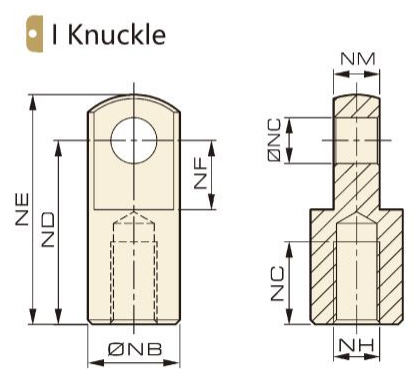

Overall Dimension

Dimension

|

Model |

NB |

NC |

ND |

NE |

NF |

NG |

NH |

NM |

Bore |

16 |

20 |

25 |

32 |

40 |

|

F-M04070I |

10 |

4 |

16 |

21 |

7 |

6 |

M4x0.7 |

4 |

Adapted fitting form |

|

|

|

|

|

|

F-M06100I |

12 |

5 |

21 |

28 |

8.5 |

8 |

M6x1 |

6 |

√ |

|

|

|

|

|

|

F-M08125I |

16 |

8 |

30 |

40 |

11 |

15 |

M8x1.25 |

8 |

|

√ |

|

|

|

|

|

F-M10125I |

20 |

10 |

40 |

52 |

15 |

18 |

M10x1.25 |

10 |

|

|

√ |

√ |

|

|

|

F-M12125I |

24 |

12 |

48 |

62 |

24 |

18 |

M12x1.25 |

12 |

|

|

|

|

√ |