Features:

Double rod with double force for higher anti-bending and anti-twisted strength ensured durable life and perfect directional characteristics.

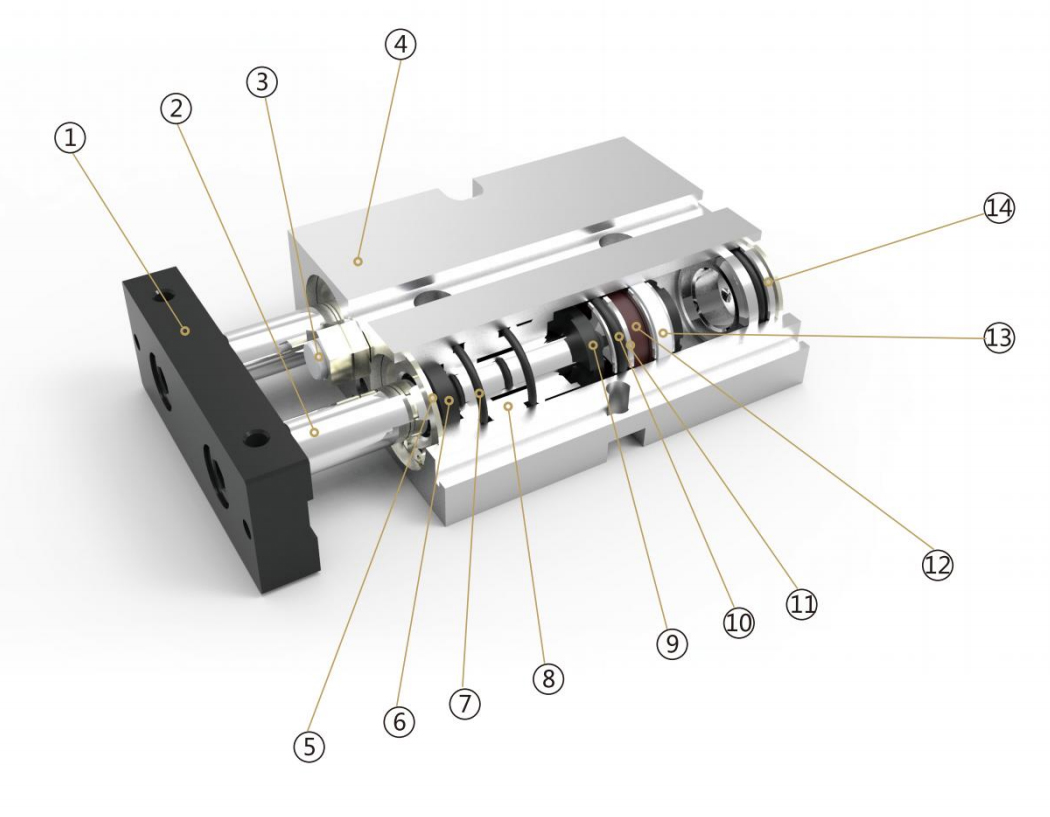

Internal Structure

Parts

| Number | Name | Number | Name |

| 1 | Fixing plate | 8 | Front cover |

| 2 | Piston rod | 9 | Anti-collision washer |

| 3 | Anti-collision head | 10 | Piston seal |

| 4 | Cylinder body | 11 | Piston |

| 5 | Circlips for holes | 12 | Magnet |

| 6 | Shaft seal | 13 | Anti-friction ring |

| 7 | O ring | 14 | Back cover |

Ordering Code

*TN Series attached magnetic ring.

*Sensor model JEL-1l,please refer to P173 for the specific ordering code.

Symbol

Specification

|

Bore (mm) |

10 |

16 |

20 |

25 |

32 |

|

Working Medium |

Air |

||||

|

Operation |

Double Acting |

||||

|

Operation Pressure Range |

0.15~1.0MPa |

||||

|

Ensure Pressure Resistance |

1.5MPa |

||||

|

Operation Temperature Range |

-10~70°C |

||||

|

Operation Speed Range |

30~500 mm/s |

||||

|

Adjustable Stroke |

-10〜0 mm |

||||

|

Cushion |

Not Available |

Cushion Gasket |

|||

|

Presion Of Non-Rotating |

±0.4° |

±0.3° |

|||

|

Port Size |

M5x0.8 |

1/8 |

|||

*The Max. operating pressure is subject to the Max. load of hydralic buffer.

Stroke

| Bore (mm) | Standard Stroke | Max.Stroke | Allowable Stroke |

| 10 | 10 20 30 40 50 6070 | 70 | 100 |

| 16 | 10 20 30 40 50 60 70 80 90 100 125150 | 150 | 200 |

| 20 | 10 20 30 40 50 60 70 80 90 100 125 150 | 150 | 200 |

| 25 | 10 20 30 40 50 60 70 80 90 100 125 150 | 150 | 200 |

| 32 | 10 20 30 40 50 60 70 80 90 100 125 150 | 150 | 200 |

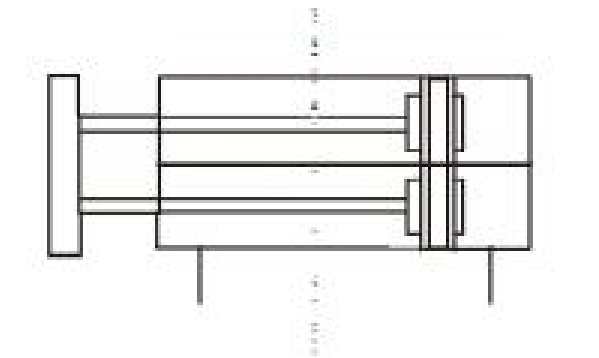

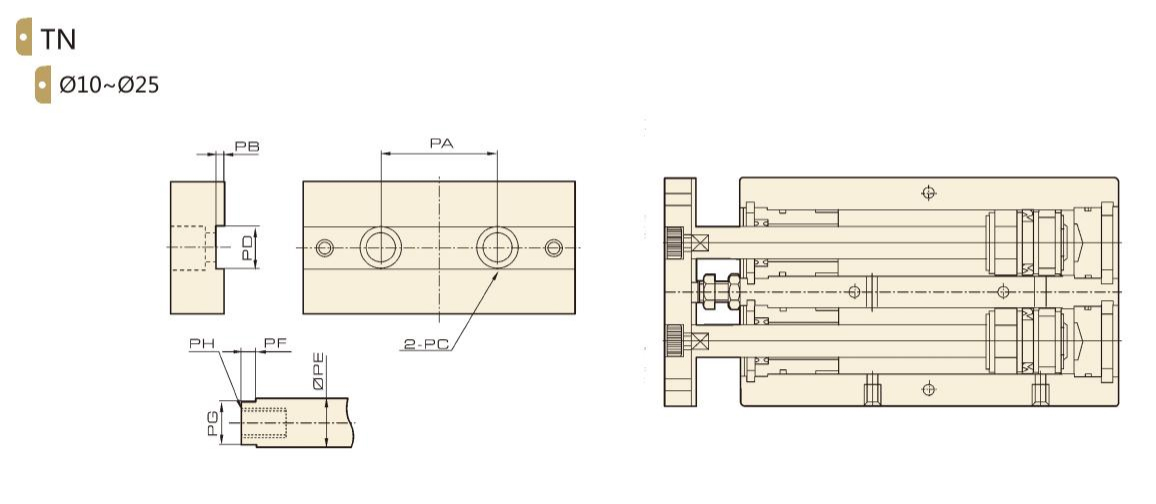

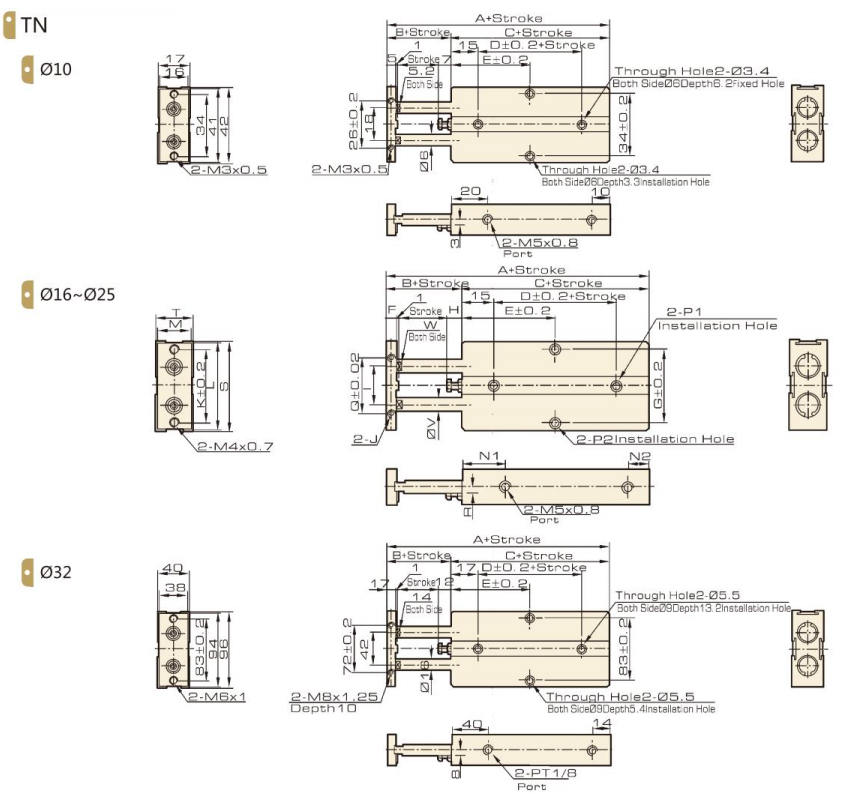

Overall Dimension

Dimension

| Bore/Symbol | PA | PB | PC | PD | PE | PF | PG | PH |

| 10 | 18 | 0.5 | ∅6.2 deep 3.5 mm, Through Hole:∅4.5 | 5.2 | 6 | 3 | 5 | M3×0.5 deep 5mm |

| 16 | 24 | 1 | ∅7.8 deep 4.6 mm, Through Hole:∅4.5 | 6.2 | 8 | 3 | 6 | M4×0.7 deep 46mm |

| 20 | 28 | 1 | ∅11 deep 6.8 mm, Through Hole:∅4.5 | 8.2 | 10 | 3 | 8 | M6×1 deep 48mm |

| 25 | 34 | 1 | ∅11 deep 6.8mm, Through Hole:∅4.5 | 10.2 | 12 | 3 | 10 | M6×1 deep 48mm |

| 32 | 42 | 2 | ∅17 deep 12 mm, Through Hole:∅4.5 | 14.2 | 16 | 3 | 14 | M10×1.5 deep 14mm |

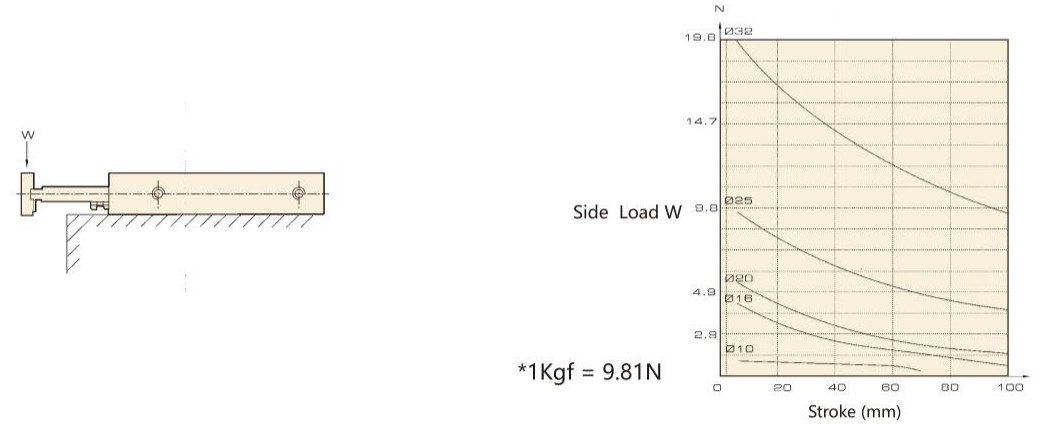

Allowable size load

Overall Dimension

|

Bore Symbol |

A |

B |

C |

D |

E |

F |

G |

H |

I |

|||||||||||

|

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

125 |

150 |

|||||||||

|

16 |

68 |

15 |

53 |

20 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

87.5 |

100 |

8 |

47 |

6 |

24 |

|

20 |

78 |

20 |

58 |

20 |

35 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

87.5 |

100 |

10 |

55 |

9 |

28 |

|

25 |

81 |

19 |

62 |

30 |

40 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

92.5 |

105 |

10 |

66 |

8 |

34 |

| Bore Symbol | J | K | L | M | N1 | N2 | P1 | P2 | Q | R | S | T | V | W |

| 16 | M4×0.7 deep 5 | 47 | 53 | 20 | 22 | 10 | Double side:∅7.5 Deep:7.2mm, Through Hole:∅4.5 | Double side: ∅8 Deep:4.4mm, Through Hole: ∅4.5 | 34 | 3 | 54 | 21 | 8 | 6.2 |

| 20 | M4×0.7 deep 5 | 55 | 61 | 24 | 25 | 12 | Double side:∅7.5 Deep:7.2mm, Through Hole:∅4.5 | Double side: ∅8 Deep: 4.4mm, Through Hole: ∅4.5 | 44 | 3.5 | 62 | 25 | 10 | 8. 1 |

| 25 | M4×0.8 deep 6 | 66 | 72 | 27 | 30 | 12 | Double side:∅7.5 Deep:7.2mm, Through Hole:∅4.5 | Double side: ∅8 Deep:4.4mm, Through Hole: ∅4.5 | 56 | 7 | 73 | 30 | 12 | 10.2 |

| Bore Symbol | A | B | C | D | E | |||||||||||||||

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | ||||||||||||||

| 10 | 63 | 12 | 51 | 10 | 30 | 30 | 35 | 40 | 45 | 50 | 55 | |||||||||

| 32 | 108 | 30 | 78 | 35 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | ||||

| 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 102.5 | 115 | |||||||||