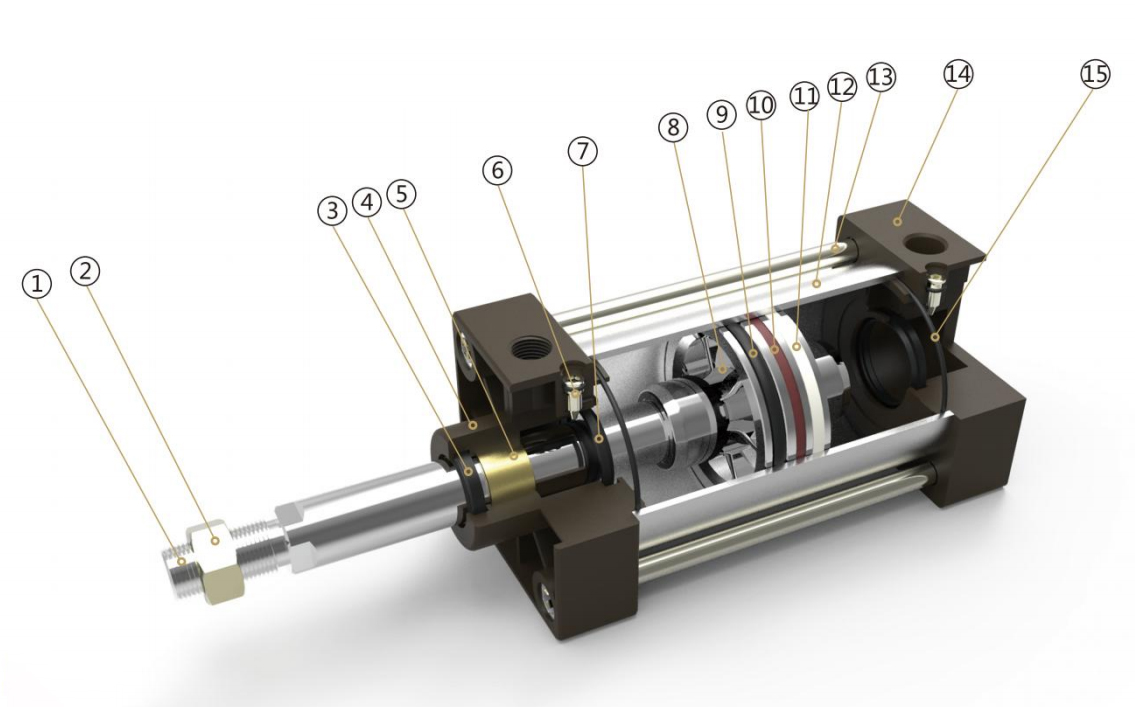

Internal Structure

Parts

| Number | Name | Number | Name |

| 1 | Piston rod | 9 | Piston seal |

| 2 | Hexagon nut | 10 | Magnet |

| 3 | Shaft seal | 11 | Anti-friction ring |

| 4 | Front cover | 12 | Barrel |

| 5 | Copper tube | 13 | Pull rod |

| 6 | Cushion adjust screw | 14 | Back cover |

| 7 | Cushion seal | 15 | O ring |

| 8 | Piston |

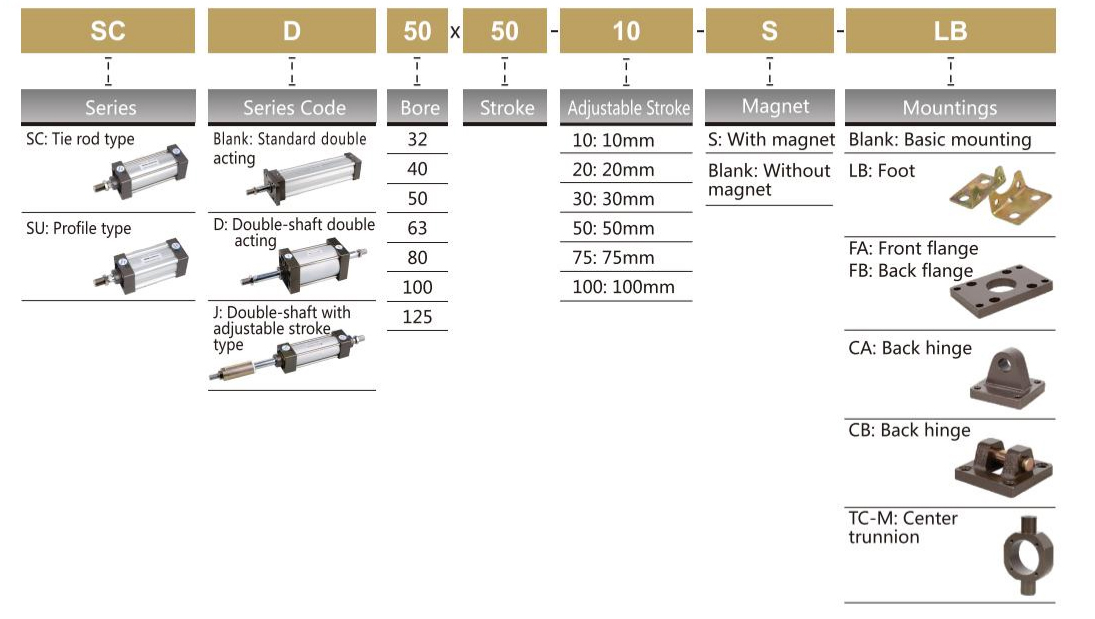

Ordering Code

*Sensor model JEL-2L,please refer to P173 for the specific ordering code.

Specification

|

Bore (mm) |

32 |

40 |

50 |

63 |

80 |

100 |

125 |

|

Operation |

Double Acting |

||||||

|

Working Medium |

Air |

||||||

|

Mountings |

Basic FA FB CA CB LB TC TC-M |

||||||

|

Operating Pressure Range |

1 ~ 9.0Kgf/cm2 |

||||||

|

Proof Pressure |

13.5Kgf/cm2 |

||||||

|

Operating Temperature Range |

-20〜80℃ |

||||||

|

Operating Speed Range |

50〜800mm/s |

||||||

|

Cushion |

Adjustable Cushion |

||||||

|

Adjustable Cushion Stroke |

20mm |

26mm |

|||||

|

Port Size |

G1/8” |

G1/4" |

G3/8" |

G1/2" |

|||

*SCD, SCJ mountings: FA, FB, LB, TC and Tc-M type.

Stroke

| Bore | Standard Stroke | Max. Stroke | Allowable Stroke |

| 32 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 1000 | 2000 |

| 40 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 | 1200 | 2000 |

| 50 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 2000 |

| 63 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 80 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 100 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

| 125 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

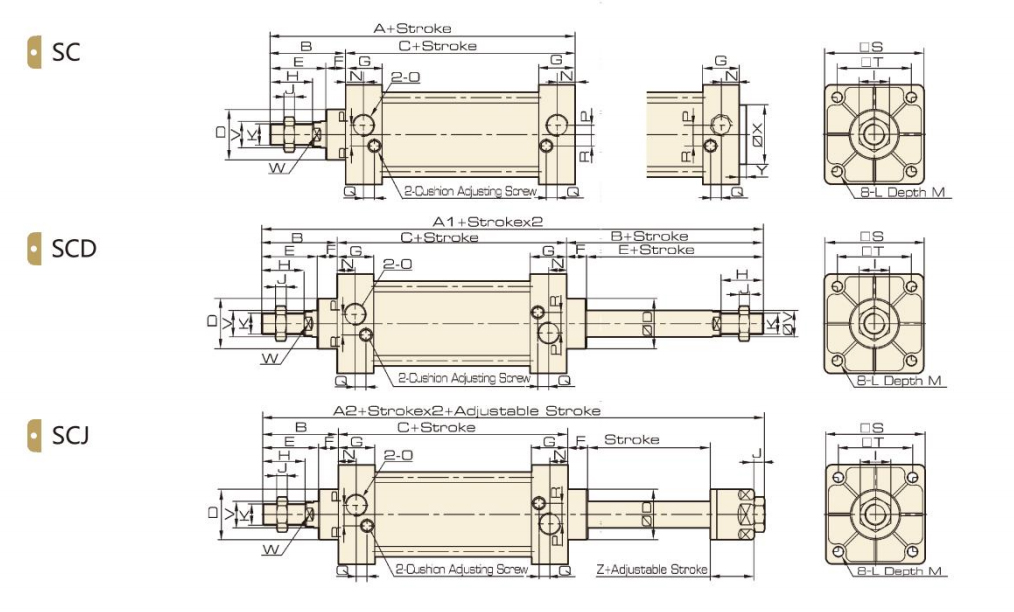

Overall Dimension

Dimension

| Bore/Symbol | A | A1 | A2 | B | C | D | E | F | G | H | I | J | K | L | ||||||||

| 32 | 140 | 187 | 182 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | 17 | 6 | M10×1.25 | M6 | ||||||||

| 40 | 141 | 191 | 185 | 48 | 93 | 32 | 34 | 15 | 27.5 | 24 | 17 | 7 | M12×1.25 | M6 | ||||||||

| 50 | 150 | 207 | 196 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16×1.5 | M6 | ||||||||

| 63 | 153 | 210 | 199 | 57 | 96 | 38 | 42 | 15 | 27.5 | 32 | 23 | 8 | M16×1.5 | M8 | ||||||||

| 80 | 183 | 258 | 243 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20×1.5 | M10 | ||||||||

| 100 | 189 | 264 | 249 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | 26 | 10 | M20×1.5 | M10 | ||||||||

| 125 | 226 | 330 | 313 | 104 | 122 | 55 | 70 | 34 | 33 | 54 | 40 | 10 | M27×2 | M12 | ||||||||

| Bore/Symbol | M | N | O | P | Q | R | S | T | V | W | Z | |||||||||

| 32 | 9.5 | 13.5 | G1/8 | 3.5 | 7.5 | 7 | 45 | 33 | 12 | 10 | 21 | |||||||||

| 40 | 9.5 | 1.5 | G1/4 | 6 | 8.2 | 9 | 50 | 37 | 16 | 14 | 21 | |||||||||

| 50 | 9.5 | 13.5 | G1/4 | 8.5 | 8.2 | 9 | 62 | 47 | 20 | 17 | 23 | |||||||||

| 63 | 9.5 | 13.5 | G3/8 | 7 | 8.2 | 8.5 | 75 | 56 | 20 | 17 | 23 | |||||||||

| 80 | 11.5 | 16.5 | G3/8 | 10 | 9.5 | 14 | 94 | 70 | 25 | 22 | 25.5 | |||||||||

| 100 | 11.5 | 16.5 | G1/2 | 11 | 9.5 | 14 | 112 | 84 | 25 | 22 | 25.5 | |||||||||

| 125 | 15.5 | 16.5 | G1/2 | 10 | 10 | 11 | 140 | 110 | 32 | 27 | 30 | |||||||||