Features:

1. Front cover with DU bearing, good guiding performance and wear resistance.

2. The shaft sealing material used PU material, PU material has high strength, good toughness, wear resistance, oil resistance, aging resistance, etc.

3. Riveting technology for the piston rod and piston to improve concentricity.

4. There are two reverse bar positioning on each side to enhance the load capacity for smoother operation.

5. Reduced noise when running inside with rubber crashpad.

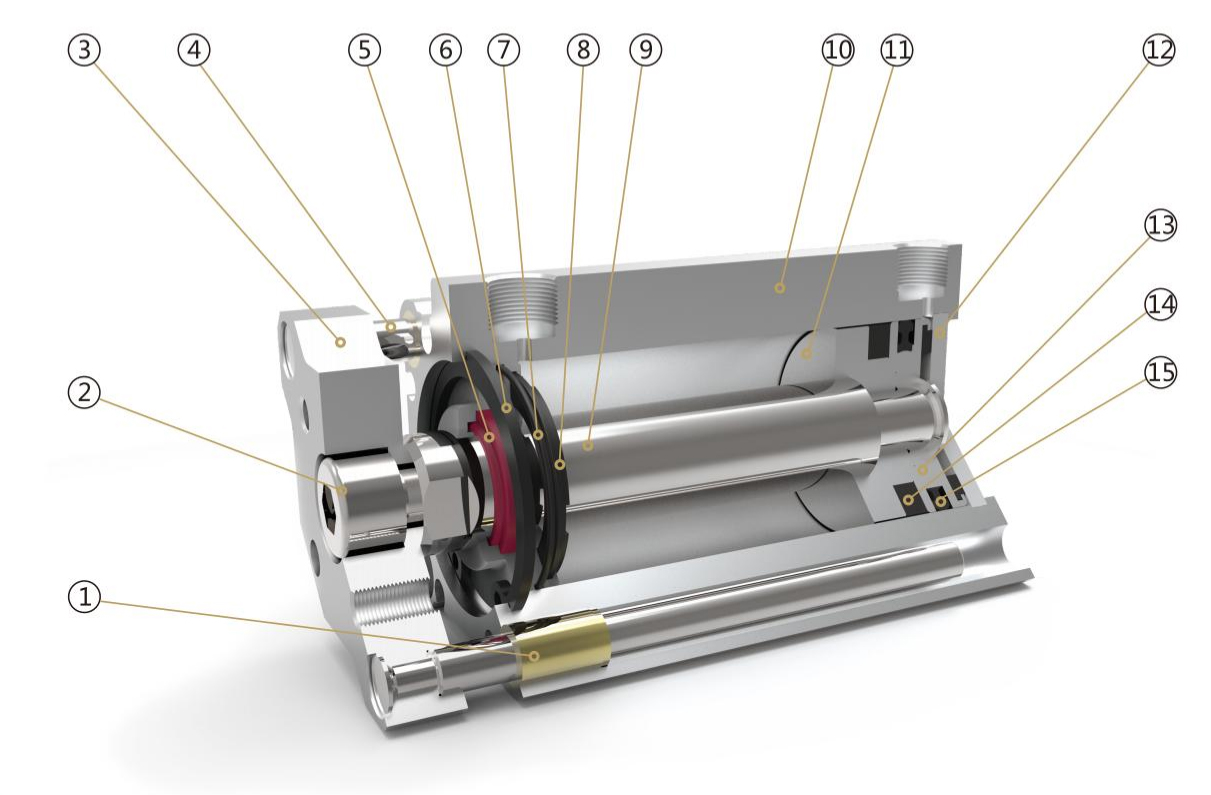

Internal Structure

Parts

|

Number |

Name |

Number |

Name |

|

1 |

Copper tube |

9 |

Piston rod |

|

2 |

Socket head screw |

10 |

Barrel |

|

3 |

Fixed plate |

11 |

Magnet base |

|

4 |

Guide rod |

12 |

Back cover |

|

5 |

Dust ring |

13 |

Piston |

|

6 |

Circlips for holes |

14 |

Magnet |

|

7 |

O ring |

15 |

C ring |

|

8 |

Anti-collision gasket |

|

|

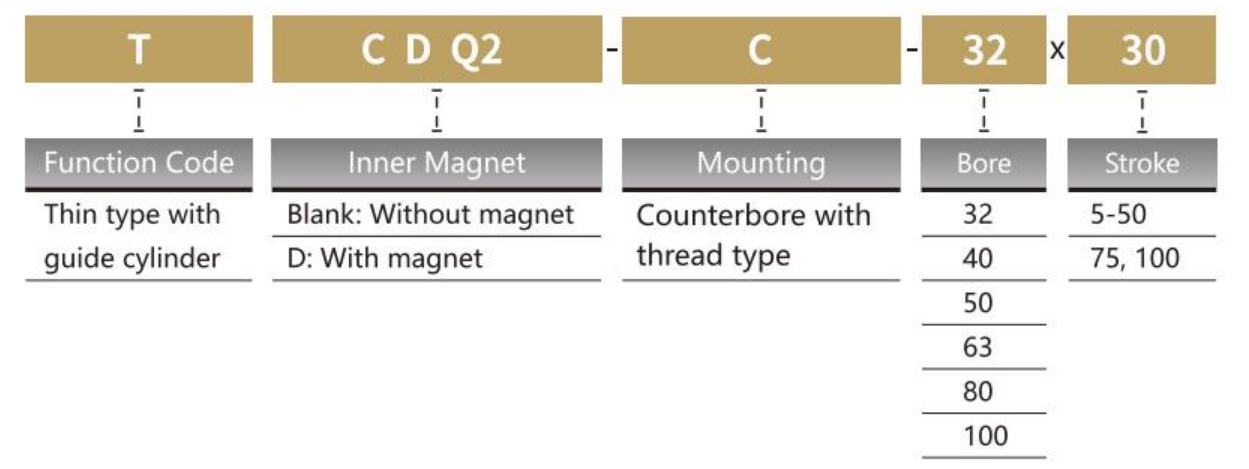

Ordering Code

*Sensor model JEL-07,please refer to P173 for the specific ordering code.

Specification

|

Bore (mm) |

32 |

40 |

50 |

63 |

80 |

100 |

|

|

Operation |

Double Acting |

||||||

|

Working Medium |

Air |

||||||

|

Operating Pressure Range |

Double Acting |

0.1 〜1.0MPa |

|||||

|

Proof Pressure |

1.5MPa |

||||||

|

Operating Temperature Range |

-20~80oC |

||||||

|

Operating Speed Range |

Double Acting |

30 〜500mm/s |

30 〜350mm/s |

30 〜250mm/s |

|||

|

Port Size |

G1/8 |

G1/4 |

G3/8 |

||||

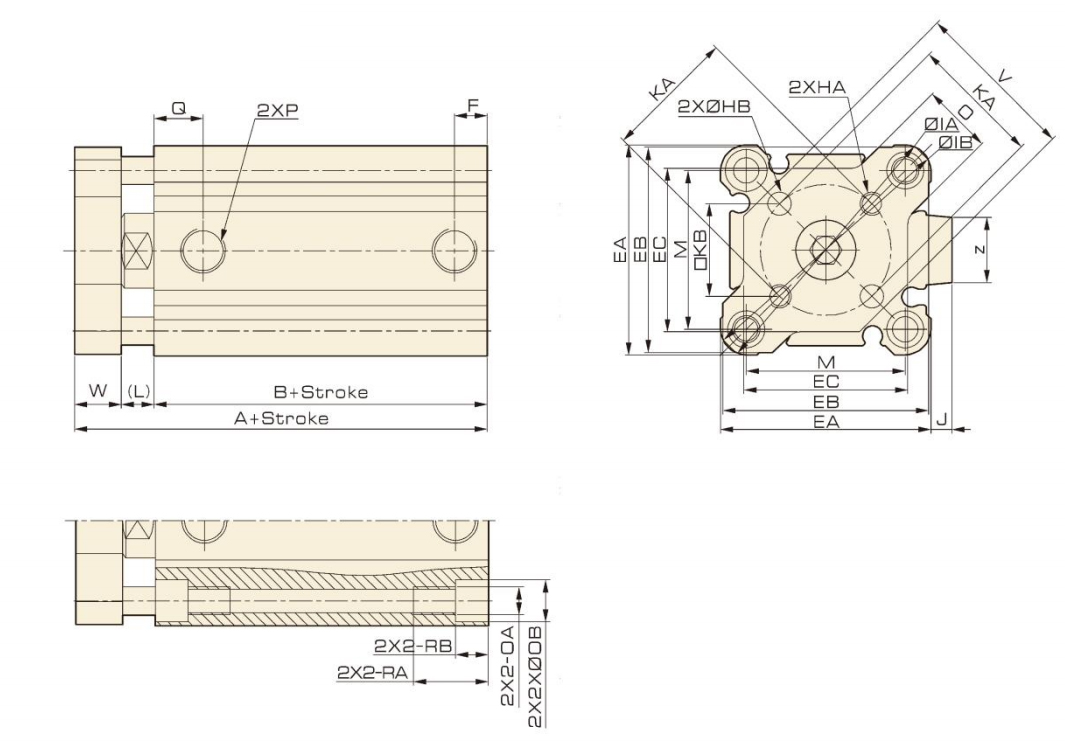

Overall Dimension

Dimension

|

Bore/Symbol |

Stroke Range(mm) |

Without magnet |

With magnet |

EA |

EB |

EC |

||||||||||||

|

A |

B |

F |

Q |

P |

A |

B |

F |

Q |

P |

|||||||||

|

- |

IN |

TF |

- |

IN |

TF |

|||||||||||||

|

32 |

5 |

40 |

23 |

5.5 |

11.5 |

M5X0.8 |

- |

- |

50 |

33 |

7.5 |

10.5 |

G1/8 |

PT1/8 |

NPT1/8 |

45 |

44 |

35 |

|

10-50 |

7.5 |

10.5 |

G1/8 |

PT1/8 |

NPT1/8 |

|||||||||||||

|

75- 100 |

50 |

33 |

||||||||||||||||

|

40 |

5-50 |

46.5 |

29.5 |

8 |

11 |

G1/8 |

PT1/8 |

NPT1/8 |

56.5 |

39.5 |

8 |

11 |

G1/8 |

PT1/8 |

NPT1/8 |

52 |

51.5 |

38 |

|

75-100 |

56.5 |

39.5 |

||||||||||||||||

|

50 |

5-50 |

50.5 |

30.5 |

10.5 |

10.5 |

G1/4 |

PT1/4 |

NPT1/4 |

60.5 |

40.5 |

10.5 |

10.5 |

G1/4 |

PT1/4 |

NPT1/4 |

62 |

61 |

48.5 |

|

75-100 |

60.5 |

40.5 |

||||||||||||||||

|

63 |

5-50 |

56 |

36 |

10.5 |

15 |

G1/4 |

PT1/4 |

NPT1/4 |

66 |

46 |

10.5 |

15 |

G1/4 |

PT1/4 |

NPT1/4 |

77 |

76 |

59 |

|

75-100 |

66 |

46 |

||||||||||||||||

|

80 |

5-50 |

67.5 |

43.5 |

12.5 |

16 |

G3/8 |

PT3/8 |

NPT3/8 |

77.5 |

53.5 |

12.5 |

15 |

G3/8 |

PT3/8 |

NPT3/8 |

98 |

97 |

75 |

|

75-100 |

77.5 |

53.5 |

||||||||||||||||

|

100 |

5-50 |

79 |

53 |

13 |

23 |

G3/8 |

PT3/8 |

NPT3/8 |

89 |

63 |

13 |

23 |

G3/8 |

PT3/8 |

NPT3/8 |

117 |

116 |

92.5 |

|

75-100 |

89 |

63 |

||||||||||||||||

|

Bore/Symbol |

HA |

OA |

HB |

IA |

IB |

J |

KA |

KB |

L |

M |

N |

OB |

RA |

RB |

V |

W |

Z |

O |

|

32 |

M5X0.8 |

M6X1.0 |

5+0.2 0 |

60 |

58.5 |

4.5 |

28±0.02 |

19.8 |

7 |

34 |

5.5 |

9 |

17 |

7 |

35 |

10 |

14 |

15 |

|

40 |

M5X0.8 |

M6X1.0 |

5+0.2 0 |

69 |

67.5 |

5 |

33±0.02 |

23.3 |

7 |

40 |

5.5 |

9 |

17 |

7 |

42 |

10 |

14 |

15 |

|

50 |

M6X1.0 |

M8X1.25 |

6+0.2 0 |

86 |

84.5 |

7 |

42±0.02 |

29.7 |

8 |

50 |

6.6 |

11 |

22 |

8 |

54.5 |

12 |

19 |

16 |

|

63 |

M6X1.0 |

M10X1.5 |

6+0.2 0 |

103 |

100 |

7 |

50±0.02 |

35.4 |

8 |

60 |

9 |

14 |

28.5 |

10.5 |

68 |

12 |

19 |

19 |

|

80 |

M8X1.25 |

M12X1.75 |

8+0.2 0 |

132 |

129 |

6 |

65±0.02 |

46 |

10 |

77 |

11 |

17.5 |

35.5 |

13.5 |

86 |

14 |

25 |

22 |

|

100 |

M10X1.5 |

M12X1.75 |

10+0.2 0 |

156 |

153 |

6.5 |

80±0.02 |

56.6 |

10 |

94 |

11 |

17 |

35.5 |

13.5 |

108 |

16 |

25 |

25 |